Next Generation Wastewater Treatment

& Infrastructure Solutions

EQUIPMENT PACKAGES FOR SPECIFYING ENGINEERS, UTILITY OPERATORS AND END-USERS

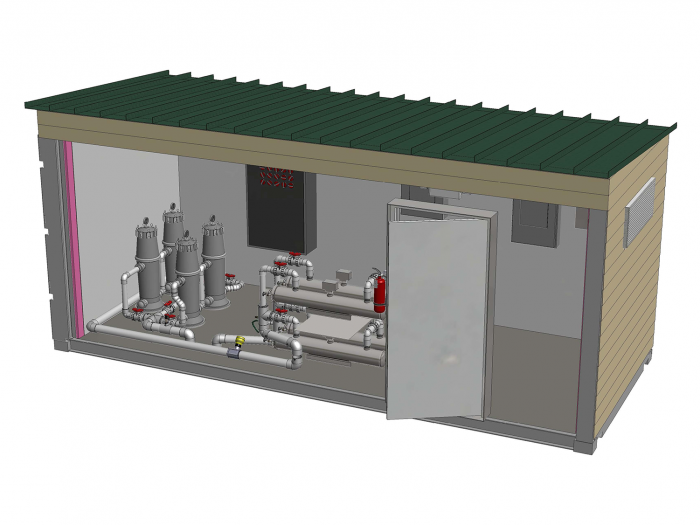

- Plug and Play Treatment Systems for FAST Installation & Commissioning

- Wastewater Treatment Packages for Decentralized Applications

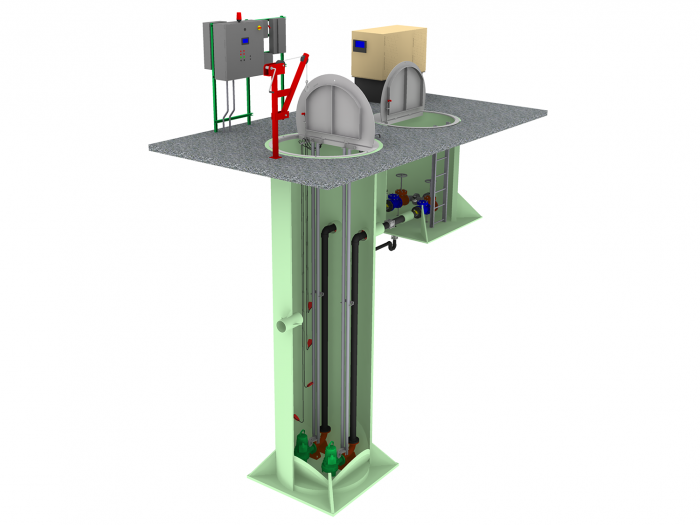

- Factory Assembled Turn-Key Wastewater Lift Station Systems

- Structural Plastic Tank Design & Manufacturing

- Custom Engineered Wastewater Treatment Solutions

- Advanced Autonomous Operations with Remote Monitoring & Control

STANDARD AND CUSTOM PRODUCTS

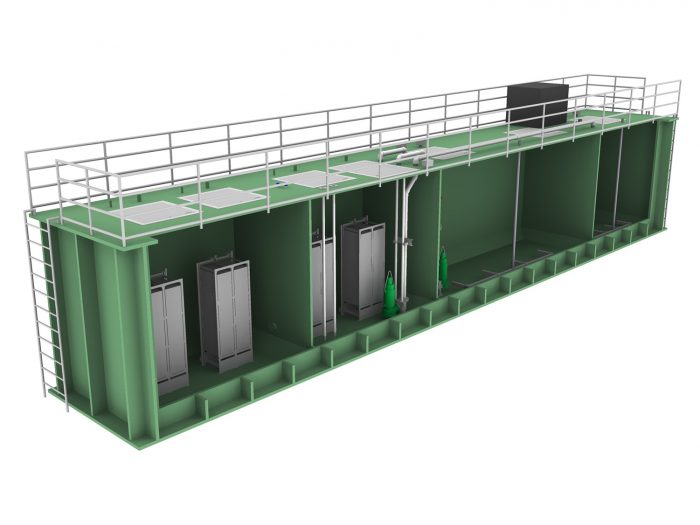

Modular Water Systems provides a broad selection of standardized and custom engineered wastewater treatment products, packaged lift stations, and ancillary wastewater infrastructure solutions for agricultural, commercial, industrial, and municipal customers. Wastewater collection, treatment, and disposal systems reflect a substantial investment in both time and money and given the importance of protecting the environment and our precious water resources, Modular Water Systems strives to deliver the industry’s most durable, sustainable, and affordable equipment packages. Our utilization of heavy plastic manufacturing combined with the integration of emerging treatment technologies creates a robust combination of capabilities that will significantly improve system performance, substantially extend continuous duty service life, and dramatically reduce operating costs.

MODULAR WATER SYSTEMS’ CORPORATE MISSION AND VISION REFLECT THE FOLLOWING

- Single-Point-of-Delivery Equipment Systems

- Advanced Treatment for Nutrient Removal & Wastewater Reuse

- Singular Focus on Product Durability and Sustainability

- Decentralized Wastewater Utility Applications

- Implementation of 100-year Wastewater Infrastructure Solutions

- Investment in advanced heavy plastic manufacturing

- Standardized Systems that save time and money

- Custom Design and Manufacturing to suit unique customer needs

- Autonomous System Operation supported by real-time monitoring and remote control

- Process Support and System Optimization

- Design-Build and Design-Build-Operate Delivery Models

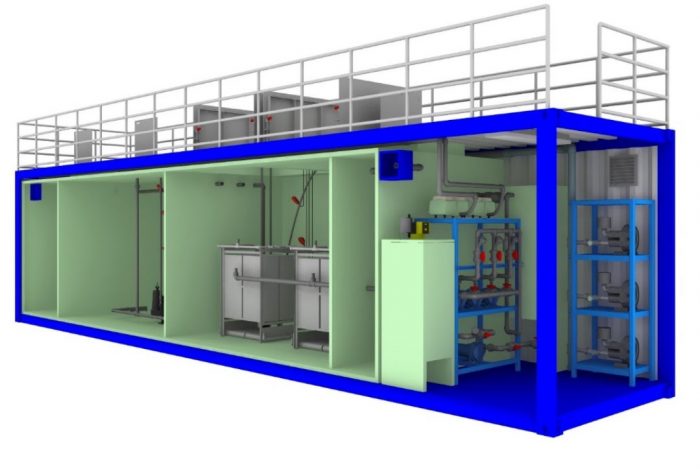

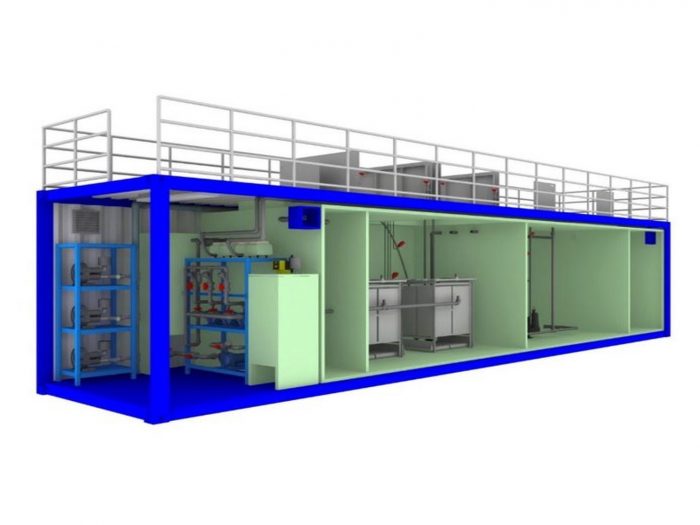

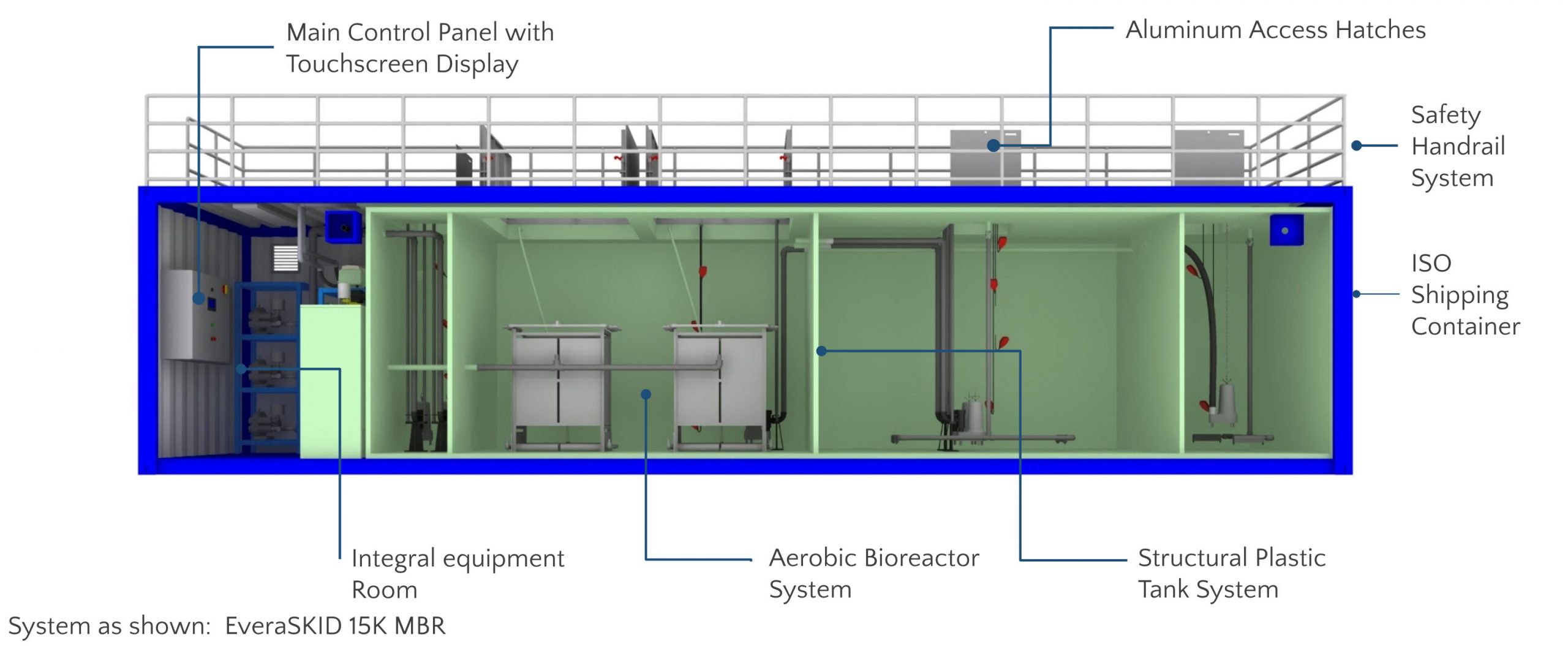

WATER SYSTEM IN A BOX™

THE STAGES OF MODULAR TREATMENT

Stage 1: Raw Wastewater enters the system via a Headworks Box or Primary Clarifier

Stage 2: Screened and or pre-treated wastewater flows to the on-board Equalization Chamber

Stage 3: Screened and or pre-treated wastewater is pump dosed to the Aerobic Treatment Chamber

Stage 4: The aerobic treatment chamber uses beneficial microorganisms to transform and remove harmful organics and pollutants.

Stage 5: A clarification process removes and retains solids and biomass (microorganisms) while discharging a high-quality effluent.

Stage 6: A final disinfection process ensures the high-quality effluent is pathogen free and safe to release to the environment.

Note: Modular Water Systems can provide Secondary, Advanced Secondary, and Tertiary Treatment Systems. While similar in function, each system will have different chambers and internal functionality to meet the Buyer’s required effluent quality.

MODULAR INFRASTRUCTURE EQUIPMENT PACKAGES

Modular Water Systems equipment packages remove the guesswork and tedious time-consuming tasks of selecting the right equipment for each specific sub-assembly that when assembled, must integrate into a complex and proper functioning water infrastructure system. We take what was difficult and make it incredibly easy with a guarantee that the system will work as intended. Designing and or purchasing a wastewater lift station or wastewater treatment system must be as easy, painless, and fun as buying a new car, refrigerator, or Smart TV

UPGRADE TO MODULAR

MODULAR WATER SYSTEMS is challenging the “status quo” of how wastewater infrastructure systems are designed, manufactured, delivered, and operated. While telecommunications, renewable energy systems, electric cars, and the internet have evolved rapidly over the last 20 years, the wastewater industry still relies upon and deploys construction methods and infrastructure solutions that have not changed in nearly 50 years and in some cases 75 years. This lack of change is reflected in poor utility service, constant maintenance, and exorbitantly high total replacement costs with the utility customers bearing the financial burden.

Modular Water Systems is driving change in the Wastewater Industry by supplying new infrastructure products that are durable, sustainable, and affordable…so the next time you need a wastewater equipment system that must last more than 20 years and not cost a king’s ransom to maintain, ask us how we can help!

WHY MODULAR WATER SYSTEMS LEAD IN POINT OF USE SOLUTIONS

- Fully-Prepackaged product line for fast rollout, 5-15% lower initial cost.

- Built in the factory and trucked in complete.

- Standardized pump stations, wastewater treatment plants, specialty agricultural, produced water, mobile deployment and more.

- High-speed design software delivers full specs and BOMs in days instead of weeks.

- Rigid self-standing thermoplastic containers last up to 100 years in the ground, minimal foundation requirements (just a pad and strapping).

- Extensive references and case studies available from projects throughout the USA.

- Enhanced Controls with Remote Monitoring & Alerts.

- Fully-designed for easier permitting.

- Certified for full compliance with most common sizes and throughputs, safety requirements, regulatory compliance. Excellent risk mitigation potential.

- Closed-loop systems for safeguarding the environment with near Zero Waste Processes.

- Patented for Basis of Design by industry visionary Daniel M. Early PE.

- Proprietary mix of product engineering, total solution development, and advanced heavy plastic manufacturing benefit Consulting Engineers and End-Users alike